Fundamentals of Hole Expansion Ratio (HER) Testing

Engineering products often contain specially shaped steel sheet parts; these parts are created using various forming processes such as shearing, punching, and stamping. In order to develop the proper part forming process, engineers must know how the material behaves under the anticipated forming conditions. These aspects of material behavior are called formability, and a wide variety of tests have been created to assess formability. One such test is the Hole Expansion Ratio (HER) test, and it is focused on a particular aspect of formability that is specific to edge failure. This article will cover the basics of HER testing, including theory, equipment, methods, results, and testing standards.

-Testing_FADI-AMT2.webp)

-Testing_G_FADI-AMT2.webp) Hole Expansion Ratio testing

Hole Expansion Ratio testingRelevance: Why Hole Expansion Ratio Testing?

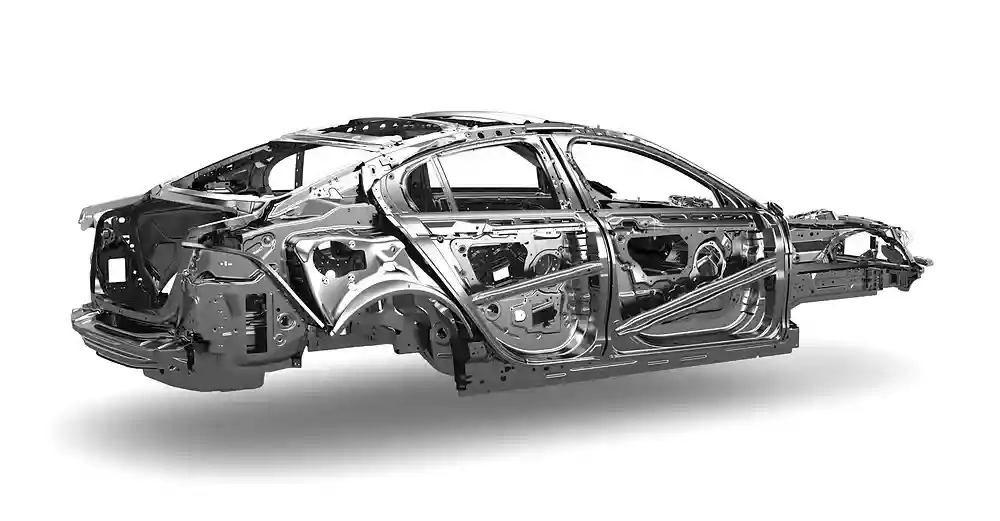

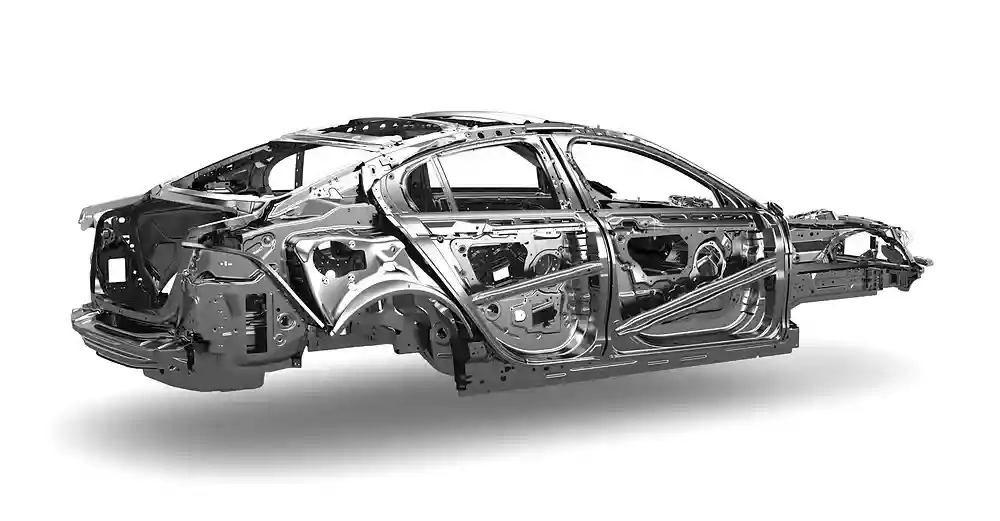

One of the most common stresses associated with sheet metal forming is edge stretching. When metal parts are punched and then stamped, the edges must stretch to accommodate the change in shape being forced by the forming equipment. Stretching the edges of a sheet metal part too much can lead to highly undesirable results like cracking, potentially ruining the part. Therefore, manufacturers require good predictions for when cracking will begin under certain types of edge stretching. These predictions can come from theoretical models, but testing is also a crucial component. The Hole Expansion Ratio (HER) test is designed to show the cracking behavior for a metallic sheet with a circular hole under uniform stretching. This forming scenario is particularly relevant in the “automotive industry”, where many parts are manufactured using stamping that follows hole punching.

Courtesy of Azuko Technical Instinute

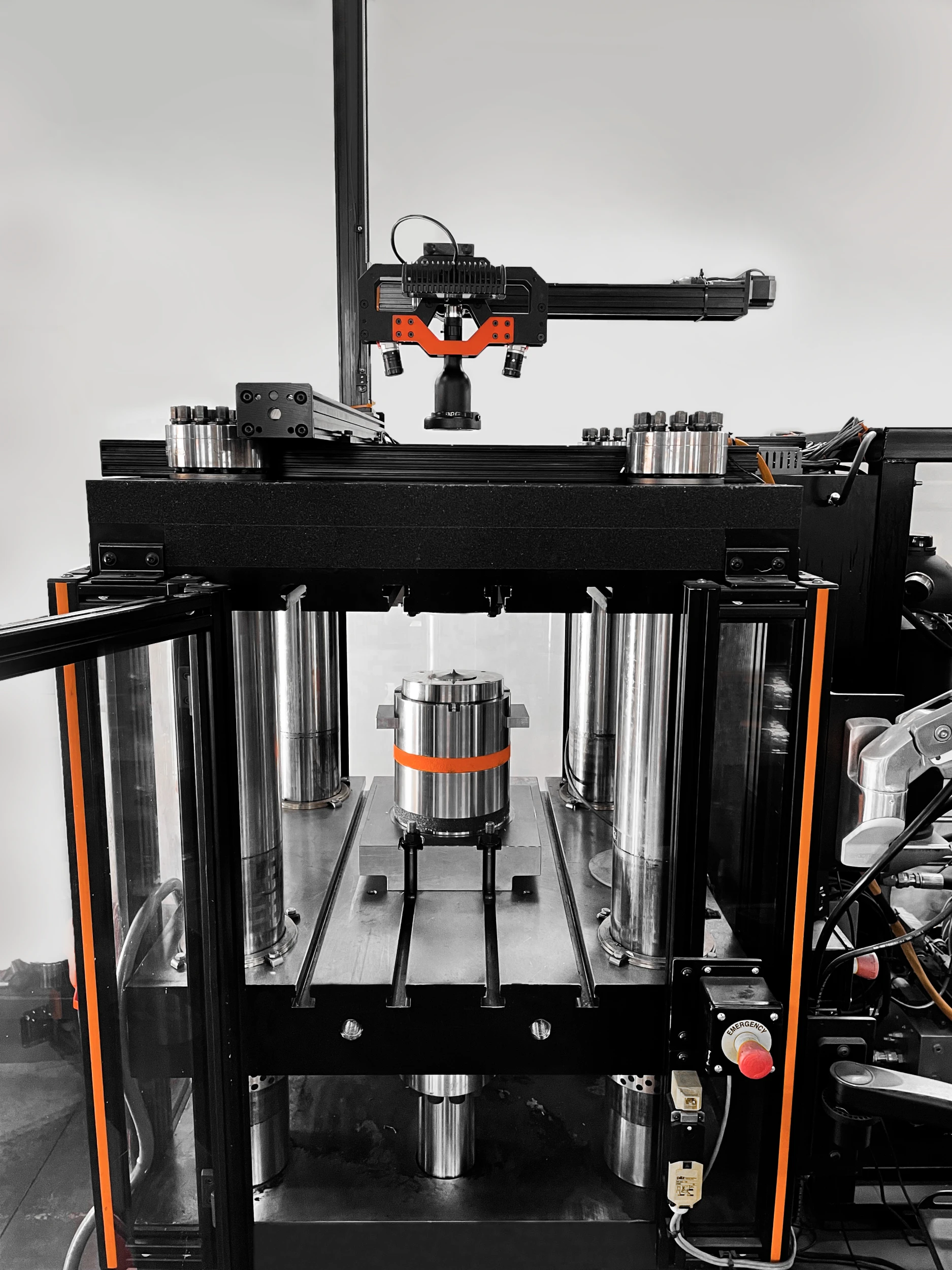

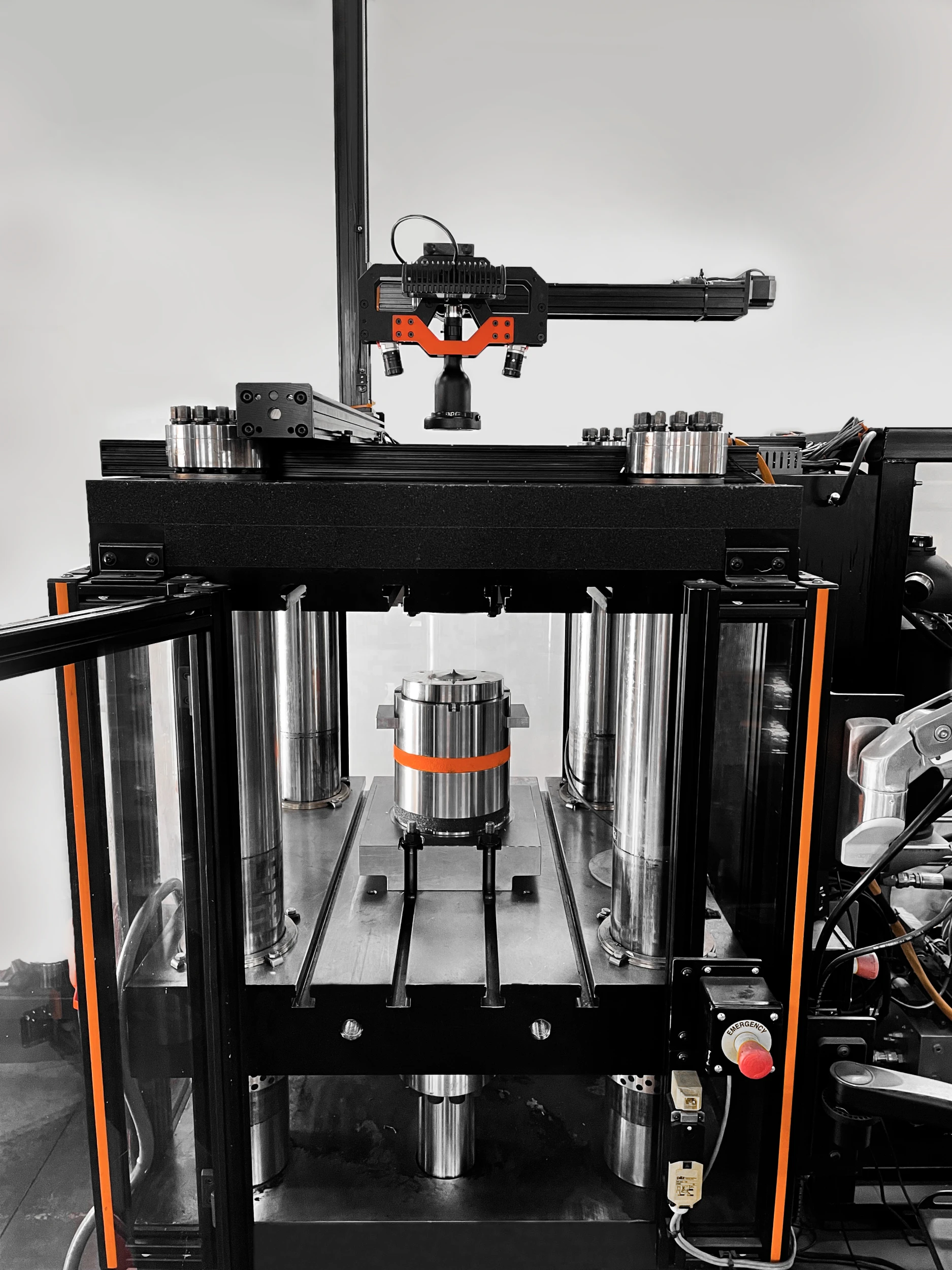

Courtesy of Azuko Technical InstinuteHER Testing Equipment

Like other sheet metal tests, such as Biaxial Tension Testing and FLC Testing, the HER test requires two fundamental forces: clamp and punch forces. Any test machine capable of producing these two forces independently can be used; that being said, HER testing does not require large forces. A Universal Formability Tester (UFT), a compact and self-contained piece of equipment driven by hydraulic cylinders that control the clamp and the punch forces, is typically used for HER testing. A dual-acting hydraulic press can also be used, but hydraulic presses are typically larger and more powerful machines than what is required for HER testing. An electromechanical load frame equipped with independent hydraulic clamping system can be also used for this testing.

SP400-Dual Acting Press System_with mi-Sensor

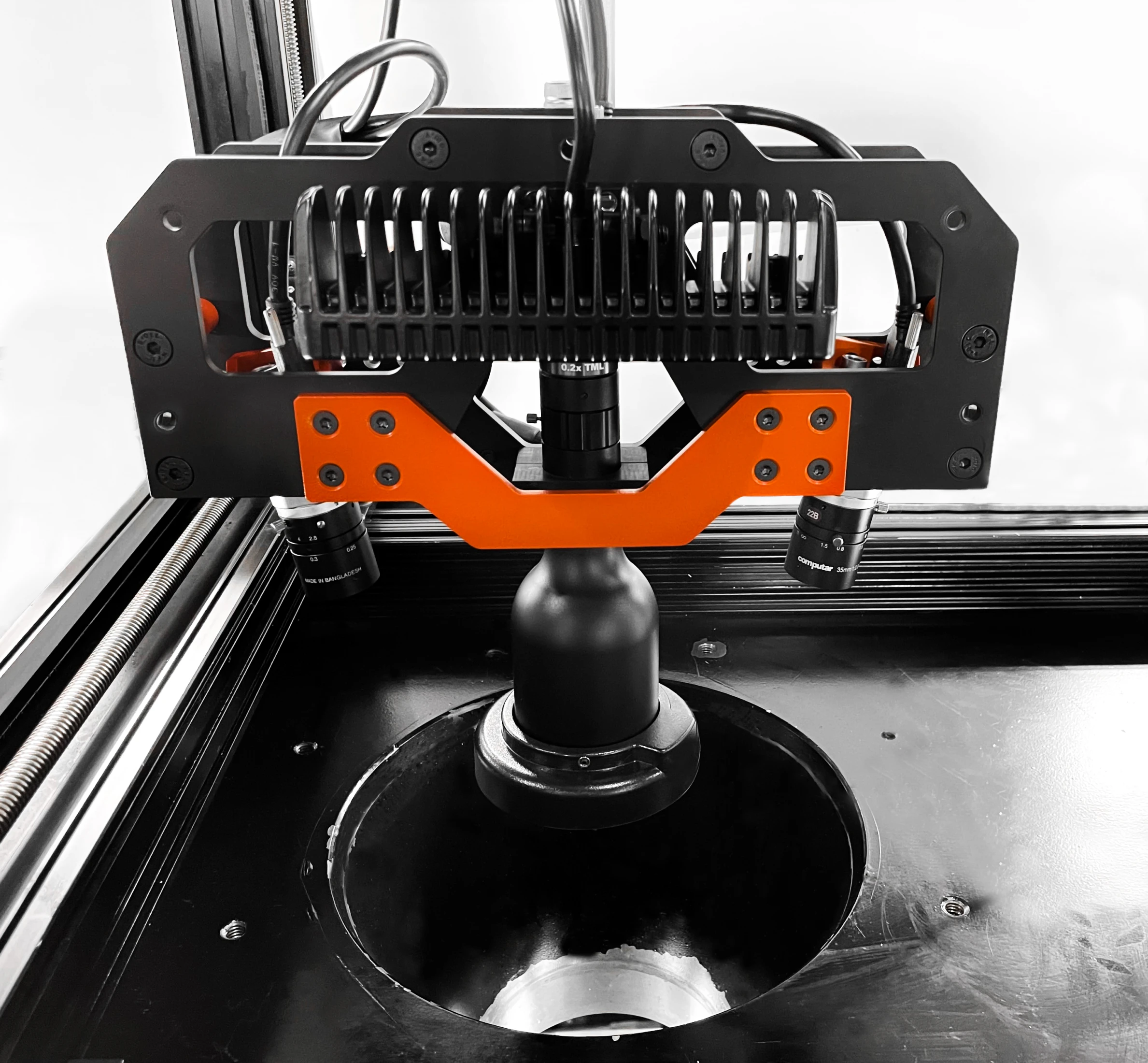

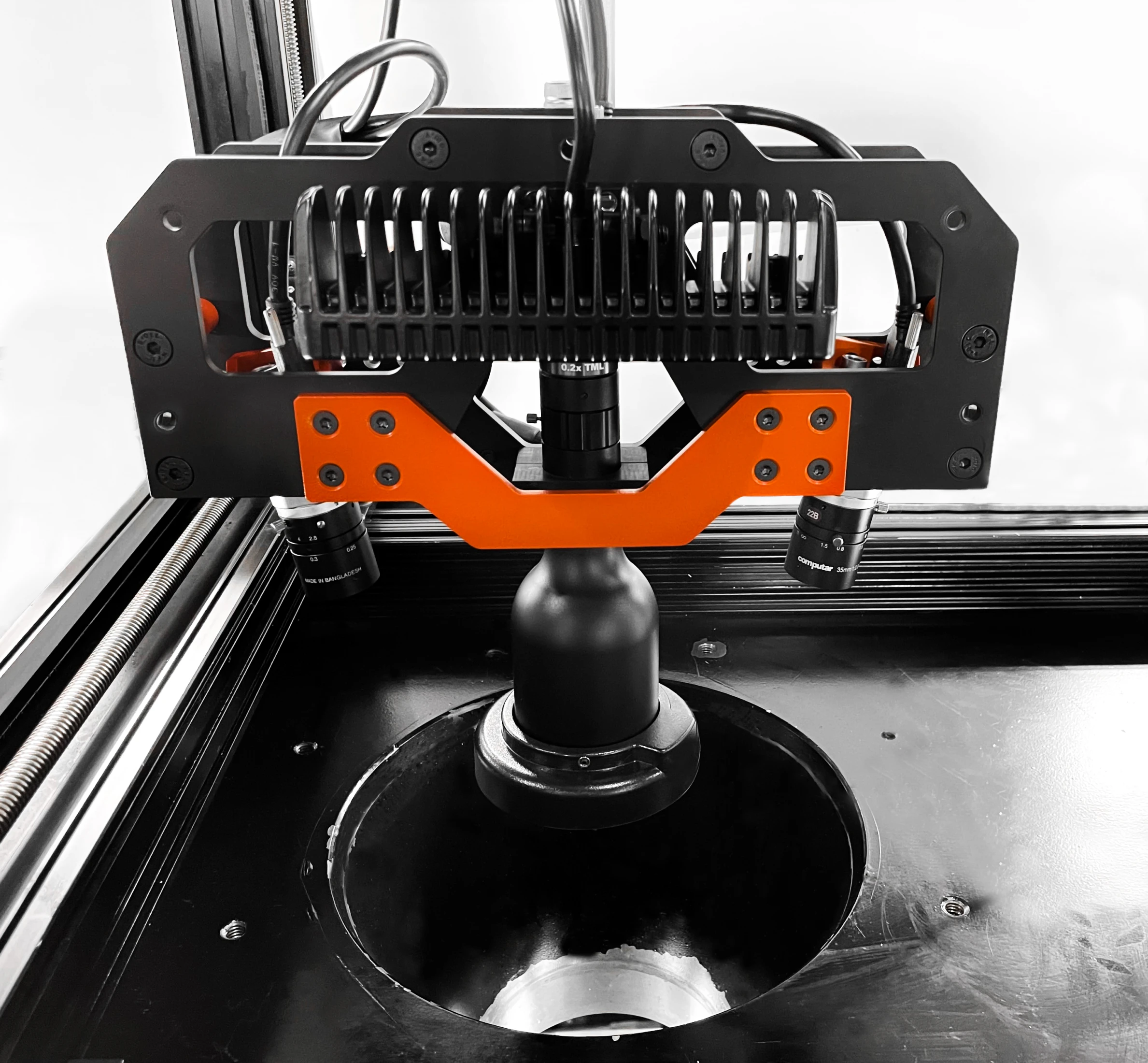

SP400-Dual Acting Press System_with mi-SensorThe only sensor necessary for HER testing is simply the means to monitor the test sample for cracking. This is most often done with one high resolution camera mounted atop the testing machine and facing downwards toward the deforming sample. During the test, the camera gives the testing engineer a real-time view of sample deformation, enabling the test to be terminated when cracking begins. Measuring forces or movement during HER testing is not required.

HER Configuration-mi-Sensor_mounted on top of SP400

HER Configuration-mi-Sensor_mounted on top of SP400HER Test Sample Geometry

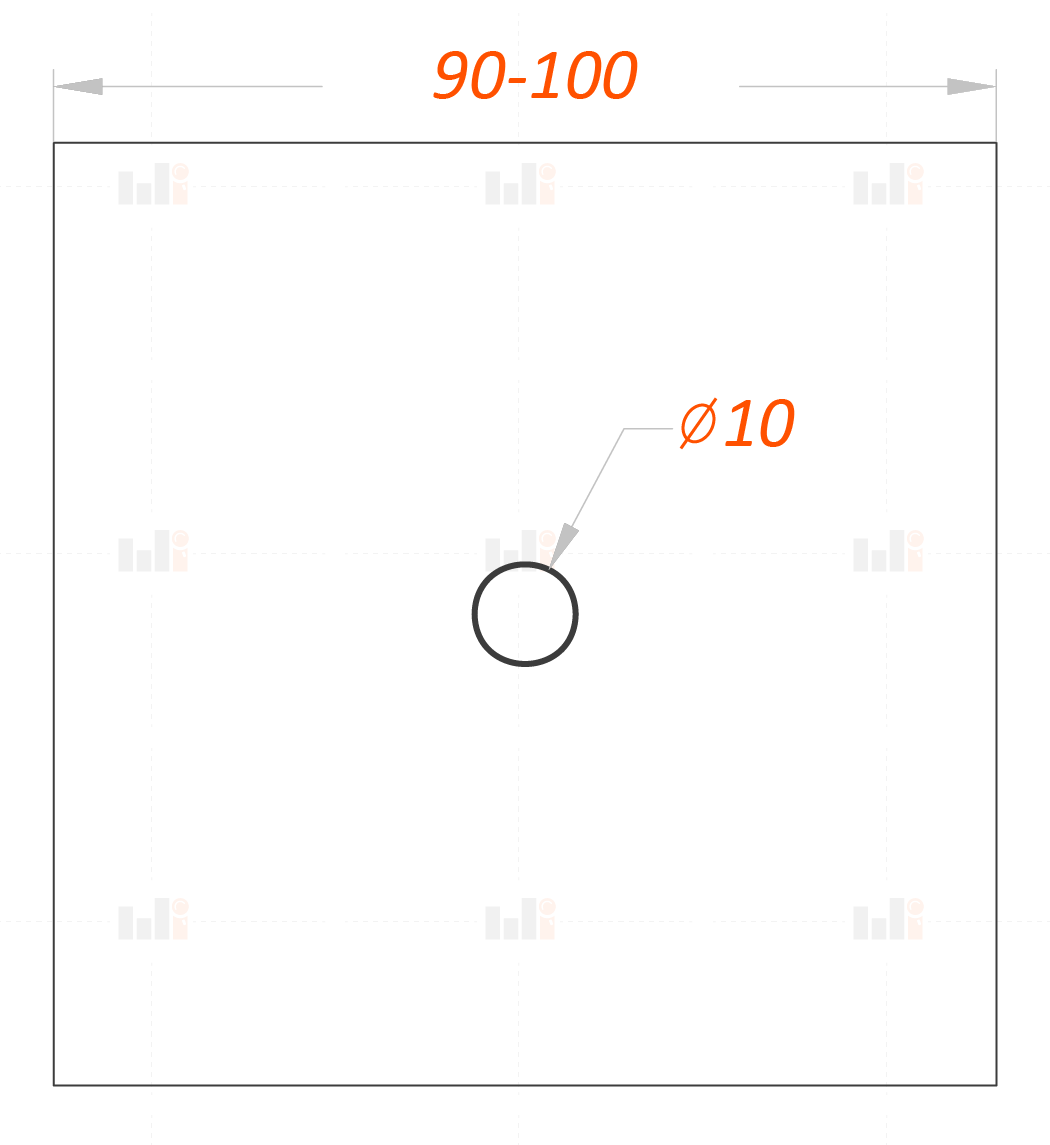

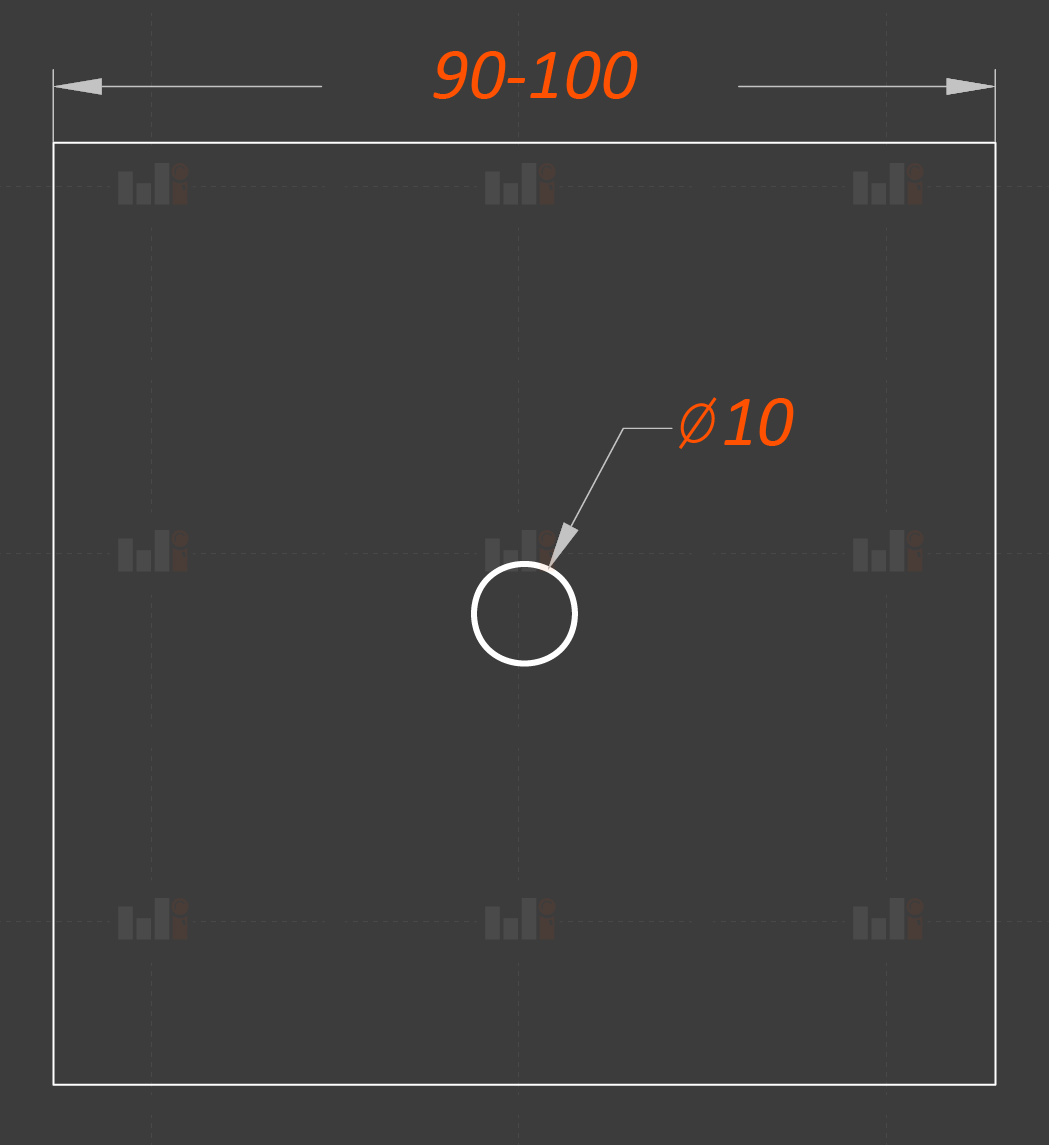

The sample geometry for the HER test is very straightforward, but the specifics of sample preparation can have large effects on testing results. Each HER sample is simply a square blank, ~90 to 100mm in size, with a small hole (10mm in diameter) introduced close to the center of the blank. To mimic actual sheet metal forming processes, the hole is typically formed by punching. One of the most important factors determining the outcome of an HER test is the quality of hole punching.

This is because the punching process induces work hardening in the edge region around the hole. It is therefore important to monitor and maintain the condition of the punching tools. Moreover, the amount of work hardening and damage to the punched material within the edge region is affected by the punching die clearance; this is why die clearance is specified in HER testing standards and it is typically set to ~12% of the sheet metal thickness. Standards attempt to limit variability in sample preparation and thus produce more consistent HER testing results.

Though not specified in the Standards, the amount of time between sample preparation (punching) and HER testing can also significantly affect the results. Because of this, many manufacturers specify an acceptable hold time between punching and testing to improve consistency.

Hole Expansion Ratio Test Sample Geometry

Hole Expansion Ratio Test Sample GeometryHER Testing Method

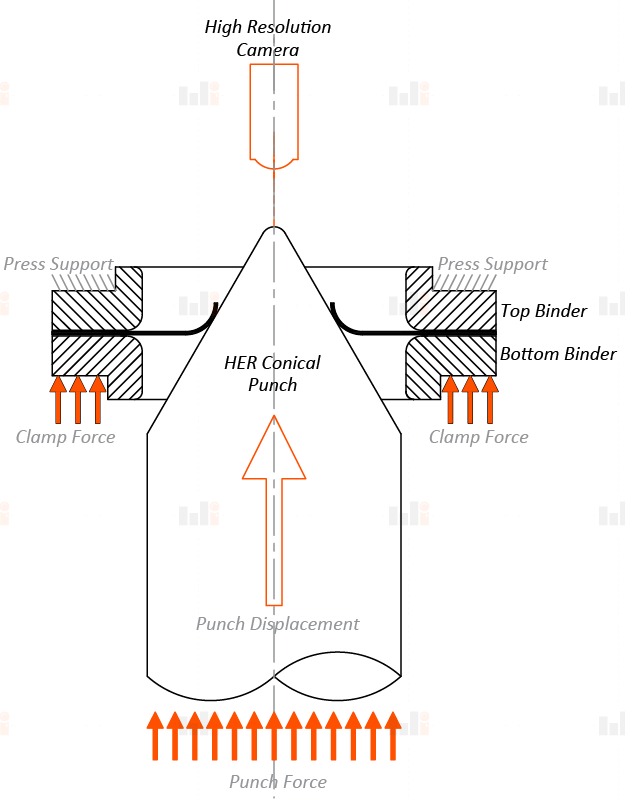

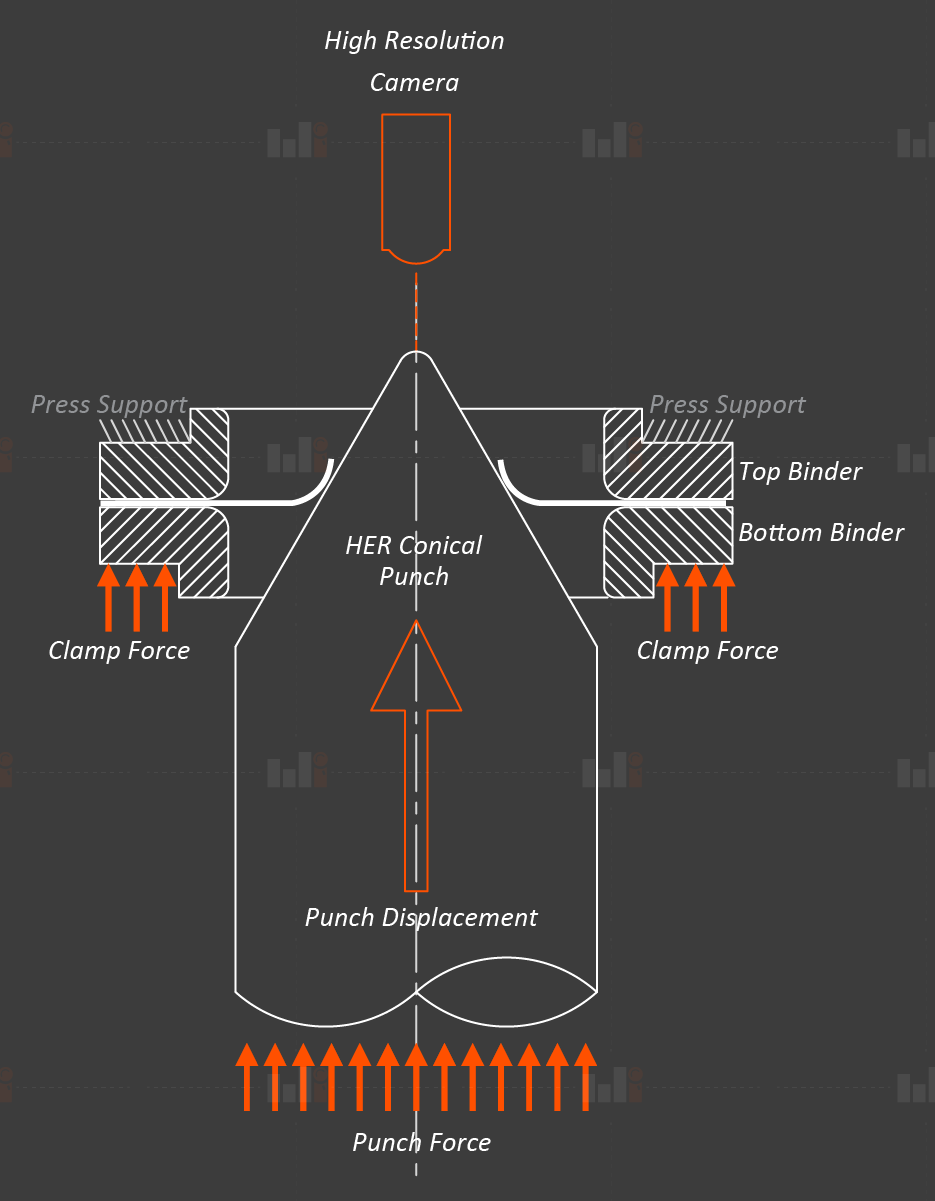

Regardless of the testing machine used, the principle of testing is straightforward. Each punched sample is placed in the testing machine and centered with respect to the conical punch.

The clamping plates simply hold the test sample firmly in place to prevent slippage, while the conical punch is driven against the hole deforming it into a crater.

Testing stops when a full crack propagates across the edge of the deformed sample (the crater). The cracked sample is then measured and the hole diameter at the point of cracking is recorded.

Hole Expansion Ratio Test Schematic

Hole Expansion Ratio Test SchematicHER Test Results

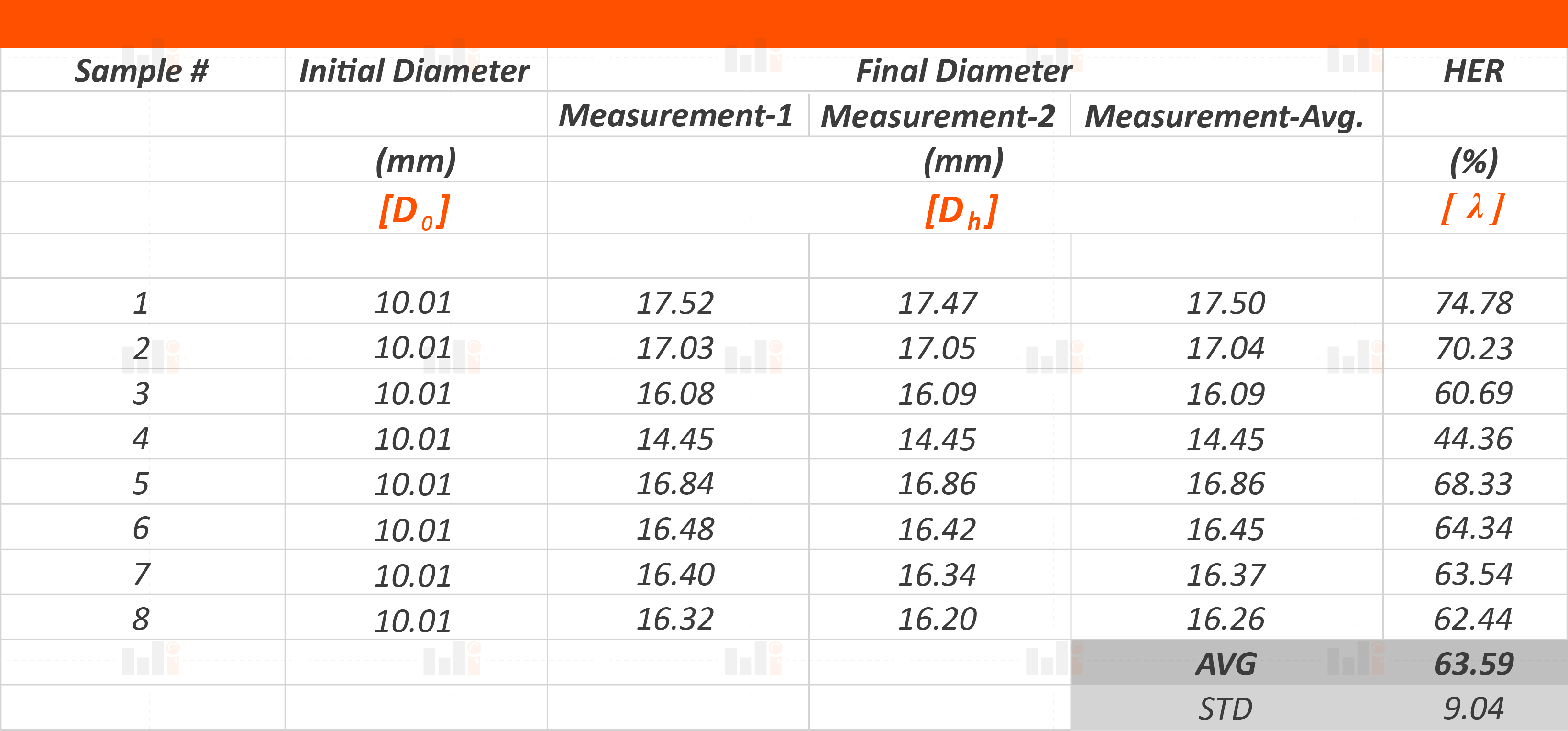

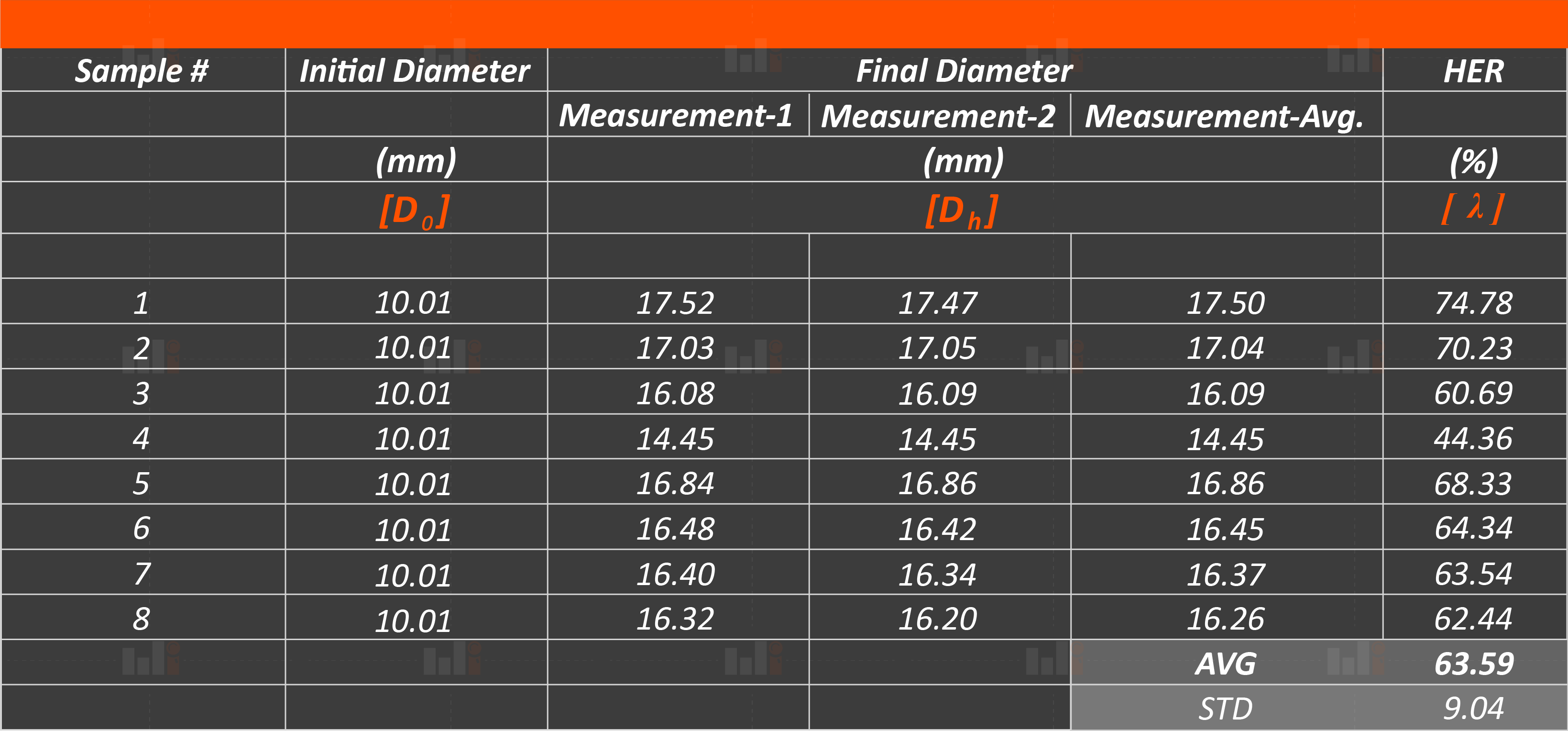

The most important piece of data obtained from the HER test is the Hole Expansion Ratio; this number is simply the ratio of the final hole diameter (right after a full crack is detected) to the initial hole diameter (10mm). While each individual test produces an HER value, the average of multiple tests is usually taken to increase accuracy. The results of each hole expansion can vary widely, so it is important to account for variability (more than 5 samples are typically tested per material). An example of the HER values extracted for a grade of steel that is commonly used in automotive body structures is given in this summary table.

Hole Expansion Ratio Testing Results

Hole Expansion Ratio Testing ResultsHER Testing Standards

HER testing is regulated primarily by the ISO 16630 testing standard.